Protecting concrete from the Inside out with Krystaline C-S-H Technology

How to make the best choice between different products for waterproofing concrete structures?

Concrete structures face a relentless assault from water and chemicals, especially in wastewater facilities, marine environments, and industrial settings. At the heart of long-lasting performance is impermeability. When concrete resists water ingress, it resists deterioration.

Krystaline C-S-H Technology offers industry-leading protection by forming a dense, water-blocking barrier within the concrete matrix. Whether applied as a treatment or integrated during casting, this technology ensures concrete durability even in the harshest environments.

Krystaline-treated concrete is engineered for resilience in areas exposed to:

• Wastewater

• Contaminated groundwater

• Seawater

• Industrial chemicals and salts

It effectively halts waterborne contaminants from penetrating concrete surfaces, preserving both the material and the steel reinforcement within.

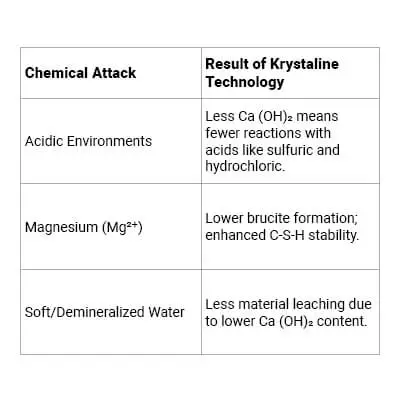

Many chemical reactions that damage concrete begin with calcium oxide (CaO) reacting with water to form calcium hydroxide (Ca (OH)₂). Krystaline C-S-H Technology reduces this reaction, protecting against:

Krystaline doesn’t just protect the concrete matrix—it also shields what’s inside:

- Sulfate-Induced Deterioration: Krystaline prevents water entry, blocking sulfate from entering, and reduces gypsum and ettringite formation.

- Chloride-Induced Corrosion: By preventing water entry, Krystaline stops chlorides from reaching the steel reinforcement.

- Alkali-Silica Reaction (ASR): Water is essential for ASR to occur. Krystaline’s impermeability interrupts the process entirely.

Krystaline C-S-H Technology is more than a waterproofing solution—it’s a durability enhancer. Its ability to prevent water ingress directly reduces long-term damage, corrosion, and maintenance costs.

Recent Posts

Compartir este artículo